دنیای مهندسی سازه های دریایی

Offshore Structures

دنیای مهندسی سازه های دریایی

Offshore StructuresThis film How to shipbuilding ocean going/فیلم چگونه ای ساخت کشتی کانتینربر اقیانوس پیما

این انیمیشن برای اول بار ارائه شده است خدا شکر می کنم به من فرصتی داده بعد از یک سال نیم وعده توانستم در این زمان آن را ارایه نمایم این انیمیشن نحوه ساخت کشتی کانتینربر اقیانوس پیما را نشان می دهد و همچنین معروفی قسمت های از کارگاه کشتی سازی راThis animation shows how to build a container ship on the ocean and the famous episode of the shipyard's

شناور کانتتینر بر اراک-PG101

این شناور اولین کشتی اقیانوس پیمای ساخت کشور است که علیرغم تحریم های صورت گرفته با کیفیت قابل رقابت با نمونه خارجی، تحویل داده شد و از تاریخ 10/03/1389 عملیاتی گردید.

همانطور که اشاره شد به خاطر تحریم ها این حرکت شد در دنیا اصولا کشتی سازی دست چند کشور است و بفیه کشورها از این کشوری کشتی سازی خرید می کنند چون مقرن به صرفه است به خاطر تکنولوژی روز این صنعت اگر این کشتی سازی نتواند سفاری داشته باشد وآن کیفیت از نظر استاندارد جهان را نداشته باشد این صنعت هم مانند بقیه صنایع ایران دچاره مشکلات مالی و تعدیل نیرو می گردد امیدوارم کشتی که در این صنایع ساخت می شود بتوان با کیفیت ها بالا خود بتوان ارز آوری داشته باشد.

یک کارگاه کشتی سازی از چند کارگاه دیگر تشگیل شده است.

کارگاه شات بلاست : شات بلاست و اعمال رنگ اولیه بر روی انواع ورق و لوله و پروفیل با عرض دهند ورودی 3100 mm

کارگاه برش: برش و لبه سازی انواع ورقهای و لوله ها با دستگاه های CNC (هوا گاز و پلاسما)

کارگاه فرم دهی: عملیات خمکاری و ورقها و لوله ها با دستگاه های رول 13 متری پرس 800 تن و دستگاه رول 3 محوره

کارگاه پانل سازی: دارای یک خط تولید نیمه اتوماتیک ساخت پانل های مسطح (TTS) می باشد که مجهز به دستگاه های مونتاژ و جوش پروفیل بر روی روق می باشد.

کارگاه ساخت سکش : این کارگاه مسقف با داشتن جرثقیل 80،100، 150 تنی به همراه فضای مناسب امکان ساخت سازه های حجیمی را تا ارتفاع 25 متر و با تناژ 400 تن فراهم می کند.

کارگاه رنگ زدایی و رنگ آمیزی

دارای سیستم هوای فشرده و کنترل دما و رطوبت

ماشین ها تراش

دستگاه برش ورق هیدرولیکی

پرس ورق هیدرولیکی

دستگاه لوله خم کن

دستگاه بوژی :

این دستگاه ها پیشرفته هستند و به صورت کنترل از راه هدایت می شوند،با قابلیت جابجایی احجام سنگین تا ظرفیت 520 تن از این دستگاه ها برای حمل و نقل فونداسیون توربین های بادی فراساحل کیسونی استفاده می شود

در آینده از همین وبلاگ نحوه ساخت فونداسیون توربین های بادی فراساحل کیسونی به توضحیات کامل نوشته شده و همچنین فیلم نحوه اجرای آن گذشته می شود.

حوضچه شناور (فلوتینگ داک) با توان بالابرى 2800 Ton براى بالا آوردن شناور هایى تا ظرفیت 8000DWT به طول 230متر و عرض 52 متر در سایت کشتى سازى وجود دارد.

Introduction to Marine Engineering, Second Edition,D.A.Taylor,Elsevier,1996

این کتاب دارای 383 صفحه می باشد درباره جزئیات کشتی و قسمت های آن نویسند شده است.

This Book Introduction to Marine Engineering, Second Edition,D.A.Taylor,Elsevier,1996

This file is Password

Password: CE-MS MS.c Bijan Mohammadi

All Text and change the color to use to download it

کلمه عبور/ Password دانلود/Download

کتاب مورد نظر با این عناوین می باشد./Book with this title

Chapter 1 Ships and machinery

Chapter 2 Diesel engines

Chapter 3 Steam turbines and gearing

Chapter 4 Boilers

Chapter 5 Feed systems

Chapter 6 Pumps and pumping systems

Chapter 7 Auxiliaries

Chapter 8 Fuel oils, lubricating oils and their treatment

Chapter 9 Refrigeration, air conditioning and ventilation

Chapter 10 Deck machinery and hull equipment

Chapter 11 Shafting and propellers

Chapter 12 Steering gear

Chapter 13 Fire fighting and safety

Chapter 14 Electrical equipment

Chapter 15 Instrumentation and control

Chapter 16 Engineering materials

Chapter 17 Watchkeeping and equipment operation

Bridge design and Evaluation LRFD and LRFR,Gongkang Fu,Wiley,2013

این کتاب دارای 438 صفحه می باشد در زمینه طراحی برزگراه و تقاطع پل ها طبق آیین نامه AASHTO می باشد وضریب ها اعمال شده و دارای مسئله کاربردی برای سازه پل می باشد.اولین چاپ این کتاب در سال 2003 چاپ شدبه عنوان کتابچه راهنما

This Book Bridge design and Evaluation LRFD and LRFR by Gongkang Fu,Wiley 2013

This file is Password

Password: CE-MS MS.c Bijan Mohammadi

All Text and change the color to use to download it

کلمه عبور/Password دانلود/Download

یک از ویژگی این کتاب می تواند از برای طراحی اسکله (Jetties) هم استفاده شود قسمت تکیه های عرشه و پایه پل

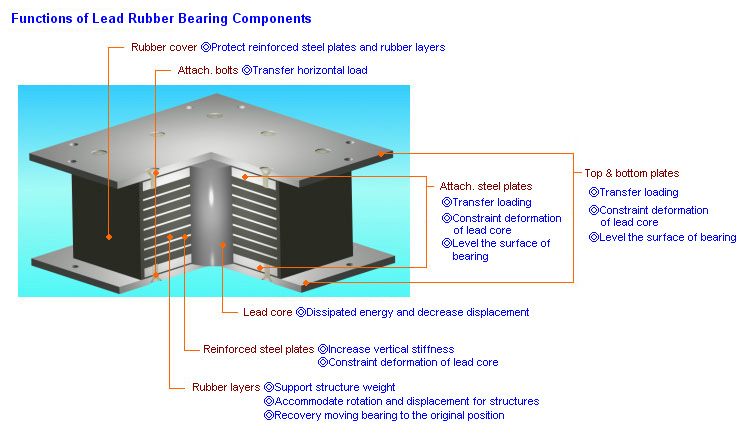

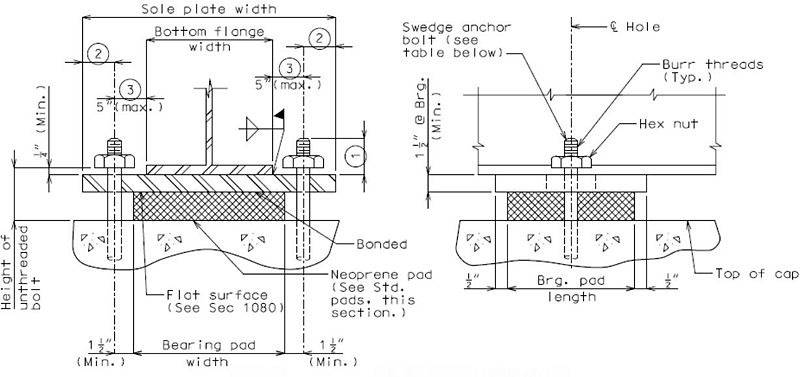

ضربه گیرهای زیر سری پل (نئوپرن) و انواع درز انبساط

نیروهای مکانیکی شامل بارهای افقی، عمودی و گشتاورهای وارده بر یک پل در ترکیب با تنشهای ناشی از انقباض و انبساط مصالح پل و خزش آنها موجب تغییر شکل در این سازه ها می شود.لذا برای کنترل این حرکات از ضربه گیرهای زیر سری پل (بالشتکهای نئوپرنی) استفاده می شود.

به زودی از همین وبلاگ فیلمی درباره آن ارایه می شود.این ضربه گیرها تلفیقی از فلز و لاستیک بوده و قطعات نگهدارنده ای هستند که در پلهای راه آهن،پلهای بتنی، پایه ساختمانها،فرودگاهها و سدها، اسکله ها که در معرض امواج بلند و خروشان قرار دارند استفاده می شوند. طراحی و تولید انواع ضربه گیرهای زیر سری پل بر اساس استانداردهای خاص و متناسب با میزان تحمل بار عمودی و افقی آنها و میزان جابجایی مجاز صورت می پذیرد.

یک زمانی به همین ضربه گیرهای پروژه های پل توی ایران به تاخیر خودن

Elastomeric Bearing & Expansion Joint

Bridge bearings are devices for transferring loads and movements from the deck to the substructure and foundations.The elastomeric bearing allows the deck to translate and rotate,,but also resists loads in the longitudinal,transverse and vertical directions. Loads are developed, and movement is accommodated by distorting the elastonmeric pad

Bearings are arranged to allow the deck to expand and contract ,but retain the deck in its correct position on the substructure

,

,

کتاب مورد نظر با این عناوین می باشد./Book with this title

Chapter1 Introduction

Bridge Engineering and Highway Bridge Network

Types of Highway Bridges

Bridge Construction and Its Relation to Design

AASHTO Specifications and Design and Evaluation Methods

Goals for Bridge Design and Evaluation

Preliminary Design versus Detailed Design

Organization of This Book

References

Chapter 2 Requirements for Bridge Design and Evaluation

General Requirements

Limit States

Constructability

Safety

Serviceability

Inspect ability

Economy

Aesthetics

Summary

References

Problems

Loads, Load Effects, and Load Combinations

Chapter 3 Loads, Load Effects, and Load Combinations

Introduction

Permanent Loads

Transient Loads

Load Combinations

References

Problems

Chapter 4 Superstructure Design

Introduction

Highway Bridge Superstructure Systems

Primary Components of Highway Bridge Superstructure

Deck Systems

Deck-Supporting Systems

Design of Reinforced Concrete Deck Slabs

Design of Steel I Beams

Design of Prestressed Concrete I Beams

References

Problems

Chapter 5 Bearing Design

Introduction

Types of Bridge Bearing

Appropriate Selection of Bearings

Design of Elastomeric Bearings

References

Problems

Chapter 6 Substructure Design

Introduction

Piers

Abutments

Foundations

Design of Piers

Design of Abutments

References

Problems

Chapter 7 Highway Bridge Evaluation

Introduction

Inspection and Condition Rating

Load Rating

Fatigue Evaluation for Steel Components

References

Problems

Drilling Engineering,J.J.Azar & G.Robello Samuel,Pennwell,2007

این کتاب درباره مهندسی حفاری یک رشته چالش برانگیز و پیچیده نفت است. در زمینه فن آوری در دو ده گذشته این پیشرفت ها اجازه می دهد صنعت نفت در سراسر جهان از لحاظ اقتصادی و موفقیت بهره برداری حوزه نفت و گاز بهتر عمل شود.

دکتر آذر استاد ممتاز دانشگاه تولسا وباز نشسته مهندسی نفت است.او در دانشگاه در سال 1965 به عنوان استادیار در رشته مکانیک /مهندسی هوا فضا و در سال 1975 به پیشنهاد رشته مهندسی نفت و به عنوان استاد کامل مدیر دانشگاه تولسا انتخاب شد و در سال 1996 به عنوان ریئس گروه مهندسی نفت نایل گردد، در سال 2002 دکتر آذر رسما از دانشگاه بازنشسته شدبه دنبال فعالیت های خود در آموزش و مشاوره خدمت کرد. استاد آذر یک مدرس دانشگاه مشهور جهان و محقق در رشته مهندسی حفاری است .او در تمام شرکت های بزرگ نفتی و گازی در سراسر جهان کار کرده است دارای 4 کتاب درسی و بیش از 60 مقاله علمی و همچنین بیش از 100 سخنرانی در جلسات فنی و حرفه ای داشته است. او به پیشنهاد یکی از دانشگاه های دوحه قطر در سال 2004 دعوت شد و در آنجا سخنرانی کرد او به عنوان یک عضو مشورتی هیات تحریری دریایی می باشد بخشی از کتاب ایشان در زمینه حفاری دریایی می باشد.

دکتر Robrello مشاور ارشد فنی حفاری او دارای بیش از 18 سال تجربه در زمینه نفت و گاز یکی از مهارت های او برنامه ریزی ، طراحی ، برآورد هزینه ، نظارت حفاری و تکمیل عملیات، پرسنل و بررسی فنی ، نوآوری ایشان همچنین استاد دانشگاه و مدیر عامل شرکت هالی برتون و بالا تفگ حفاری در سال 1983تا 1992 به عنوان مهندس حفاری در یک شرکت نفت و گاز طبیعی مشغول به کار بوده است

This book Drilling Engineering,J.J.Azar & G.Robello Samuel,Pennwell,2007

Drilling engineering is a challenging discipline in the oil patch. It goes beyond what is found in textbooks

The technological advances in the past two decades have been very significant. These advances have

allowed the oil industry worldwide to economically and successfully exploit oil and gas fields that may have not been possible before

Dr. J. J. Azar , PhD, PE, SPE, NAE, is a professor emeritus of Petroleum Engineering at the University of Tulsa. He joined the university in 1965 as an assistant professor in Mechanical/ Aerospace Engineering, and was promoted to associate professor in 1969. In 1975, he joined the Petroleum EngineeringDepartment as full professor and Director of the University of Tulsa Drilling Research Projects, a joint oil and gas industry research program. In 1996, he stepped down from the directorship to devote full time to teaching and writing. He served as acting chairman of the Petroleum Engineering Department in 2001. Dr.Azar officially retired from the University May 31, 2002, to pursue his own activities in teaching and consulting. Professor Azar is a world-renowned lecturer and researcher in drilling engineering. As a director of drilling research, he is credited with building one of the most comprehensive and top drilling engineering curricula in the Department of Petroleum Engineering at the University of Tulsa, worldwide. He has led his graduate students to pioneering research work in areas of cuttings transport in directional well drilling, drilling fluids hydraulics, drill bit, and drill string dynamics. He is closely associated and worked with all major oil and gas companies across the globe. His contributions to the advancement of drilling technology through teaching, research, and publications are notable. He is the author and/or coauthor of four textbooks and more than 60 publications in refereed technical journals. He has given more than 100 presentations at technical meetings and professional functions. He has been invited as keynote speaker at

several technical conferences. Professor Azar was a participant speaker at the Advances in Drilling Technologies” workshop organized by the U.S. National Research Council and the National Academy of Sciences. In 2004, he was invited by the University of Chicago to be session leader and group facilitator on Materials science conference held in Doha, Qatar. He has served as a member of the SPE Education and Professionalism Technical Committee, SPE Student Chapter adviser, SPE Career Guidance and Student Development Committee, Technical reviewer, Committee Chairman/Member on the “SPE Distinguished Achievement Award for Petroleum Engineering Faculty,” Committee Chairman/Member on the “AIME Mineral Industry Education Award” and Member of Editorial Advisory Board of Offshore

Dr. Azar received the 1998 SPE Drilling Engineering Award and the 1997 SPE Distinguished Achievement Award for Petroleum Engineering Faculty. He was elected as SPE Distinguished Member for the year 2004. He was inducted into the U.S. National Academy of Engineering in Washington, D.C, in 2004. He is a registered professional engineer and a member of SPE. His areas of interest in teaching and research include: well bore fluids hydraulics, wellbore mechanics,drill bit mechanics, drill string mechanics, and well control mechanics in application to vertical, directional, horizontal, multilateral, coiled tubing, under-balanced, and slim hole drilling

Dr. G. Robello Samuel is a Senior Technical Advisor (Drilling) in the Drilling, Evaluation, and Digital Solutions division of Halliburton, where he has been since 1998. He has more than 18 years of experience in domestic and international oil/gas drilling and completion operations, management, consulting and teaching. His skills include well planning, design, cost estimates, supervision of drilling and completion operations, personnel and technical review, project management, and creative establishment of project relationships through partnering and

Innovation. Presently he is a technical and engineering lead for well planning engineering application suite for drilling, completions, and well services operations. Also he is an adjunct professor at the University of

Houston teaching advanced drilling and complex well architecture courses

He has authored or coauthored more than 50 conference and journal papers. He has given several graduate seminars at various universities. Dr. Samuel has been the recipient of numerous awards including the “CEO for A Day (Halliburton)” and “Top Gun (Drilling)” awards. He has also worked at Oil and Natural Gas Corporation, India from 1983 to 1992 as a drilling engineer. He is

Presently serving as a Review Chairman on the Society of Petroleum Engineers (SPE) Drilling and Completions Editorial Review Committee, American Society of Mechanical Engineers (ASME) Journal of Energy Resources Technology and as co-chairman of SPE Multilateral Technical Interest Group. His other professional experience includes being on the 2006–2008 drilling committee of SPE.

He holds BS and MS (Mechanical Engineering) degrees from University of Madurai, Madurai and College of Engineering Guindy, Anna University (Chennai), MS and PhD (Petroleum Engineering) degrees from the University of Tulsa. He is a member of ASME and SPE

His areas of research include wellbore fluids hydraulics, tubular design, thermal and flow phenomena and their effect on loading of wellbore tubulars, drilling and well cost optimization and downhole tool hydrodynamics

Dr. G. Robello Samuel is a Senior Technical Advisor (Drilling) in the Drilling, Evaluation, and Digital Solutions division of Halliburton, where he has been since 1998. He has more than 18 years of experience in domestic and international oil/gas drilling and completion operations, management, consulting and teaching. His skills include well planning, design, cost estimates, supervision of drilling and completion operations, personnel and technical review, project management, and creative establishment of project relationships through partnering and

Innovation. Presently he is a technical and engineering lead for well planning engineering application suite for drilling, completions, and well services operations. Also he is an adjunct professor at the University of Houston teaching advanced drilling and complex well architecture courses He has authored or coauthored more than 50 conference and journal papers. He has given several graduate seminars at various universities. Dr. Samuel has been the recipient of numerous awards including the “CEO for A Day (Halliburton)” and “Top Gun (Drilling)” awards. He has also worked at Oil and Natural Gas Corporation, India from 1983 to 1992 as a drilling engineer. He is Presently serving as a Review Chairman on the Society of Petroleum Engineers (SPE) Drilling and Completions Editorial Review Committee, American Society of Mechanical Engineers (ASME) Journal of Energy Resources Technology and as co-chairman of SPE Multilateral Technical Interest Group. His other professional experience includes being on the 2006–2008 drilling committee of SPE.He holds BS and MS (Mechanical Engineering) degrees from University of Madurai, Madurai and College of Engineering Guindy, Anna University (Chennai), MS and PhD (Petroleum Engineering) degrees from the University of Tulsa. He is a member of ASME and SPEHis areas of research include wellbore fluids hydraulics, tubular design, thermal and flow phenomena and their effect on loading of wellbore tubulars, drilling and well cost optimization and downhole tool hydrodynamics

This file is password

Password :CE-MS MS.c Bijan Mohammadi

All Text and change the color to use to download it

Download/دانلود کلمه عبور/Password

Chapter 1 Rotary Drilling for Oil and Natural Gas

Introduction

The Process of Rotary Drilling

Rotary Drilling Rigs

Rig Selection

Rotary Drilling Systems

Mud System Evaluation

Rotary System

Well Control System

Data Acquisition and Monitoring System

Special Systems for Offshore Drilling

Supplementary Problems

Nomenclature

Chapter 2 Drilling Fluids

Characteristics of a Drilling Fluid

Drilling-Fluid Selection

Classification of Drilling Fluids

Water-Based Drilling-Mud Contaminants

Drilling-Mud Properties, Field Tests, and Control

Alkalinity (Mf, Pf, Pm, Mm, P1, P2)

Mud Rheology

Drilling-Mud Additives

Supplementary Problems

Nomenclature

Chapter 3 Fluid Flow and Associated Pressures in the Rotary Rig Circulating System

Introduction

Mechanical Energy and Pressure Balance

Pressure Drop across the Bit Nozzles (Jets)

Friction Pressure Losses in the Rotary Rig Circulating System

Friction Pressure Losses in Pipes and Annuli—Laminar Flow

Friction Pressure Losses in Pipes and Annuli—Turbulent Flow

Equivalent Newtonian Viscosity

Turbulent Pipe Flow of Non-Newtonian Fluids

Turbulent Annular Flow of Non-Newtonian Fluids

Annular Friction Pressure Losses Due to Pipe Movement

Supplementary Problems

Nomenclature

References

Chapter 4 Drill Bit Hydraulics

Introduction

Pump Pressure Requirement in Rotary Drilling

Hydraulic Power Requirement

Flow Exponent (α)

Maximum Drill Bit Hydraulic Horsepower Criterion

Maximum Jet Impact Force Criterion

Supplementary Problems

Nomenclature

References

Chapter 5 Transport of Drilled Cuttings

Introduction

Factors that Affect the Transport of Drilled Cuttings

Cuttings Transport in Vertical Well Drilling

Cuttings Transport in Directional Well Drilling

Empirical Correlations for Cuttings Transport in High-Angle Wells (θ > 50°)

Supplementary Problems

Nomenclature

References

Chapter 6 Prevention and Control Mechanics of Well Blowouts

Introduction

Kick Causes

Kick Detection

Kick Prevention

Fundamentals of Well Control

Well Control System

Principles of Well Control

Commonly Used Well Control Methods

Non conventional Kick Situations

Supplementary Problems

Nomenclature

References

Chapter 7 Directional and Horizontal Well Drilling

Directional Well Drilling

Horizontal Well Drilling

Tortuosity

Supplementary Problems

Nomenclature

References

Chapter 8 Drill Bit Mechanics

Introduction

Bit Selection

Types of Drill Bits

Classification of Roller Cone Drill Bits

Drill Bit Operating Parameters

Grading of Dull Drill Bits

Classification of Drag Drill Bits

Rock Mechanics

Performance Mechanics of Drag Drill Bits

Supplementary Problems

Nomenclature

References

Chapter 9 Drill String Design

Definition and Components

Design Criteria

Buckling of the Drill String

Drill String Fatigue

Dril String Vibration

BHA Design for Directional Drilling

Deviation Tools

Supplementary Problems

Nomenclature

References

Chapter 10 Drilling Problems and Solutions

Introduction

Pipe Sticking

Loss of Circulation

Hole Deviation

Drill Pipe Failures

Borehole Instability

Mud Contamination

Producing-Formation Damage

Hole Cleaning

Hydrogen Sulfide–Bearing Zones and Shallow Gas

Equipment- and Personnel-Related Problems

Supplementary Problems

Nomenclature

References

Chapter 11Casing and Cementing Design

Drilling the Pay Zone: Selecting the Interval and the Initial Design

Initial Completion Design

Casing Design

Cementing

Supplementary Problems

Nomenclature

References

Chapter 12 Well Planning in Drilling Engineering

Introduction

Objectives

Information Needed for Effective Well Planning

Responsibilities of the Drilling Engineer

Considerations in Well Planning

The Drilling Program

Post-Well Analysis

Well Cost Estimation

Learning Curve

Cost Control in Well Drilling

Time Value of Money

Price Elasticity

Supplementary Problems

Nomenclature

Nonlinear Finite Element Methods, Peter Wriggers,Springer, 2008*

Nonlinear Finite Element Methods, Peter Wriggers,Springer2008

This file is password

Password :CE-MS MS.c Bijan Mohammadi

All Text and change the color to use to download it

Password/کلمه عبور دانلود/ Download

Chapter 1 Introduction

Chapter 2 Nonlinear Phenomena

* Geometrical Nonlinearity

Large Displacements of a Rigid Beam

Large Displacements of an Elastic System

Bifurcation Problem

Snap-Through Problem

Physical Nonlinearity

Nonlinearity Due to Boundary Conditions

Chapter 3 Basic Equations of Continuum Mechanics

* Kinematics

Motion and Deformation Gradient

Strain Measures

Transformation of Vectors and Tensors

Time Derivatives

Balance Equations

Balance of Mass

Balance of Linear and Angular Momentum

First Law of Thermodynamics

Introduction of Different Stress Tensors

Balance Equations with Respect to Initial Configuration

Time Derivatives of Stress Tensors

Constitutive Equations

Elastic Material

Elasto-Plastic Material Laws

Visco-Elastic and Visco-Plastic Material Behaviou

Incremental Form of the Material Equations

Weak Form of Equilibrium, Variational Principles

Weak Form of Linear Momentum in the Initial Configuration

Weak Form of Linear Momentum in the Current Configuration

Variational Functionals

Linearizations

Linearization of Kinematical Quantities

Linearization of Constitutive Equations

Linearization of the Variational Formulatio

Chapter 4 Spatial Discretization Techniques

* General Isoparametric Concept

One-Dimensional Interpolations

Two-Dimensional Interpolations

Three-Dimensional Interpolation

Discretization of the Weak Form

FE-Formulation of the Weak Form in Initial Configuration

Linearization of the Weak Form in the Initial Configuration

FE-Formulation of the Weak Form in the Current Configuration

Linearization of the Weak Form in the Current Configuration

Deformation Dependent Loads

Chapter 5 Solution Methods for Time Independent Problems

*Solution of Nonlinear Systems of Equations

Newton-Raphson Method

Modified Newton Scheme

Quasi-Newton Method

Damped Newton Method, Line-Search

Path-Following or Arc-Length Method

Solvers for Linear Systems of Equations

Direct Solvers

Iterative Solution Methods

Parallel Equation Solver

Examples Related to Algorithms and Equation Solvers

Rubber Block

Solid with an Inclusion

Elasto-Plastic Plate with Hole

Problems Solved on Parallel Computers

General Observations

Problems, Which Occur when Running Actual Simulations

Chapter 6 Solution Methods for Time Dependent Problems

Chapter 7 Stability Problems

Chapter 8 Adaptive Methods

Chapter 9 Special Structural Elements

Chapter 10 Special Finite Elements for Continua

Chapter 11 Contact Problems

Chapter 12 Automation of the Finite Element Method by J. Korelc